United Precision Plastics

(Manufacturers of Packaging Solutions)

Reassuring Quality

Compostability

The term “bioplastics” is actually used for two separate things:

Bio-based plastics :

-

This means that the material is (partly) derived from biomass or plants ie which are renewable sources.

-

Biomass for plastics are usually from corn, sugarcane, or cellulose. Therefore this is not fossil fuel based, hence it is also called as Green material

Biodegradable plastics :

-

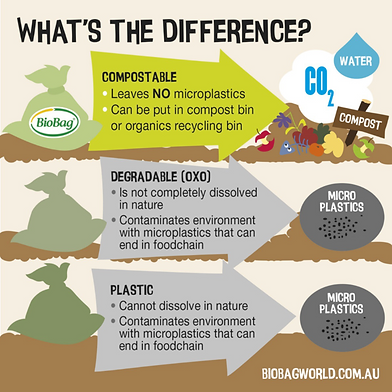

Plastics that can be completely broken down by microbes in a reasonable timeframe, given specific conditions.

-

Micro-organisms in the environment are able to convert biodegradable materials to natural substances such as water, CO2, and compost without additives within a certain time and at a particular location.

NOTE: Not all bio-based plastics are biodegradable, and not all biodegradable plastics are bio-based.

Bio-based plastics : “Beginning of Life” of plastics

Biodegradable/compostable: “End of life of plastics

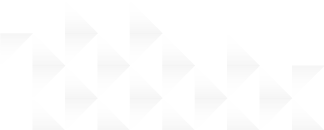

What does compostability mean ?

Fragmentation – first step in the biodegradation process, in which organic matter is broken down into microscopic fragments

Biodegradability – Complete microbial assimilation of the fragmented product as a food source by the microorganisms in the disposal environment

Compostability – Complete carbon assimilation within 180 days in an industrial compost environment.

.png)

Bio-based And Bio Degradable: These are usually materials

made from cellulose acetate (plant-based) or lactic acid-based

blends (or pure starch blends) and are used for primarily single

use plastics like cutlery or some applications across pens/toys etc.

Some examples are :

PLA : Poly Lactic Acid

PHA : Poly Hydroxyalkanoate

And other plant based cellulose compounds

They are completely biodegradable as per the standards specified

under ASTMD6400 / EN13432

Oil-Based and Bio-degradable : Traditional oil based polymers

which are biodegradable have existed for many years and usually

being used for applications such as stents, tissue engineering

and other biomaterial applications.

Some examples are :

uPBAT, PBS and PCL

.png)

CIPET: BIODEGRADABILITY TEST REQUIREMENTS

-

Biodegradation/Mineralization:

Ultimate aerobic Biodegradation ( the breakdown of organic contaminants such as carbon by microorganisms when oxygen is present) must be more than 90% within 180 days

-

Disintegration:

After 12 weeks not more than 10% of the product’s original dry mass should remain when passing through 2mm sieve

-

Ability of compost to support plant growth:

The Percentage of Seed germination should be greater than 90% for 2 different plant species.